Successful Industrial Pallet Racking Project Cases

Showcasing Our Excellence in Industrial Pallet Racking Supply

Warehouse Racking Project Cases

Explore Our Comprehensive Range of Industrial Racking Cases

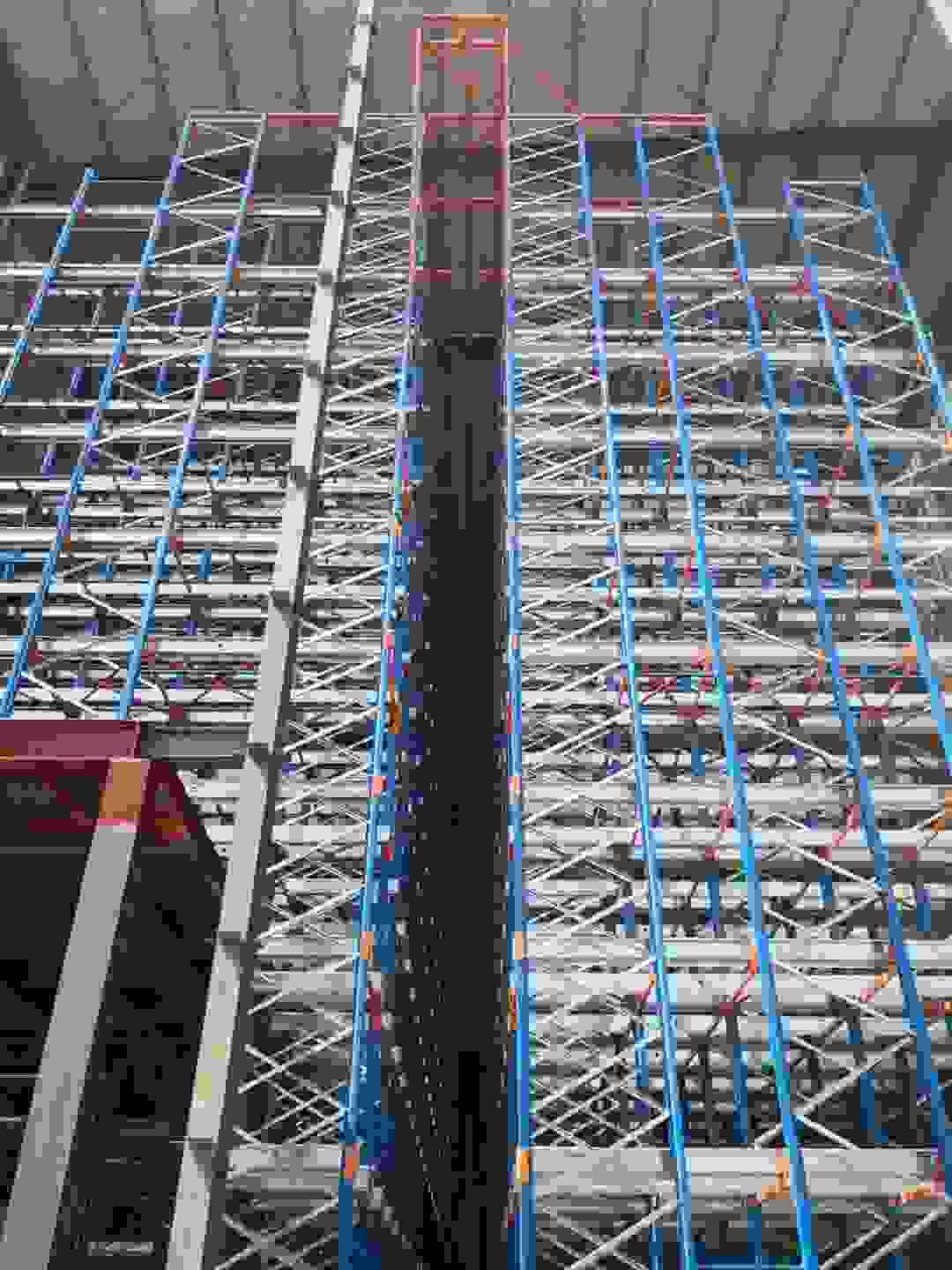

High-Bay AS/RS Racking System

Country: Mexico

Product type :AS/RS

Warehouse type: Normal Ambient

Rack sheight :26.7m

Pallet Locations:17,468

Problem: This is a high-volume setup, the end user required rapid retrival and handling.

Situation: we optimized the size of upright and beam, to make sure the stacker crane moves in the minimum distance.

Result: With advanced automation technology, this setup not only increases throughput but also enhances accuracy in inventory management, ensuring that every item is accounted for and easily accessible. Additionally, the system's modular design allows for seamless integration with existing workflows, enabling clients to adapt quickly to changing inventory needs while maintaining high operational standards. This adaptability ensures long-term sustainability and improved return on investment.

VNA (Very Narrow Aisle) Pallet Racking

Country:China

Industry: e-Commerce Giant

Project time :2021

Producttype :VNA Pallet Rack

Locations:5,584

This installation significantly improved their storage efficiency and workflow, allowing for faster order fulfillment and inventory management. Additionally, the optimized layout reduced labor costs and increased overall productivity, proving to be a vital asset for their expanding operations.

Shuttle Racking + Stacker Crane

Country:Philipines

Project time :2023

Product type :AS/RS+Shuttle

Warehouse type: Normal Ambient

Rack height :18 m

Locations:1,772Problem: The end user requires maximum pallet locations, while stacker crane aisle occupies lots of space

Situation: we work with integrator to use Stacker crane + shuttle racking

Result: This project perfectly combines efficiency and space utilization,showcasing our commitment to innovation, we provide efficient storage and retrieval solutions tailored to client needs. With a robust design and seamless operation, this system enhances productivity while maximizing space utilization, proving essential for the client's growing demands. Furthermore, the implementation of advanced control software allows for real-time monitoring and adjustments, ensuring optimal performance at all times. This capability not only boosts operational efficiency but also provides the client with valuable insights into their inventory dynamics, supporting future scalability and strategic decision-making.

4-Way Shuttle Racking System

Country: Peru

Project time :2023

Product type :4-Way Shuttle Rack

Warehouse type: Ambient temperature

Locations:7,520

Number of Shuttle: 10This advanced solution enhances operational efficiency,

Allowing for rapid retrieval and storage of goods in a compact layout. The system's versatility is ideal for various inventory types, ensuring optimal use of space and streamlined workflows.

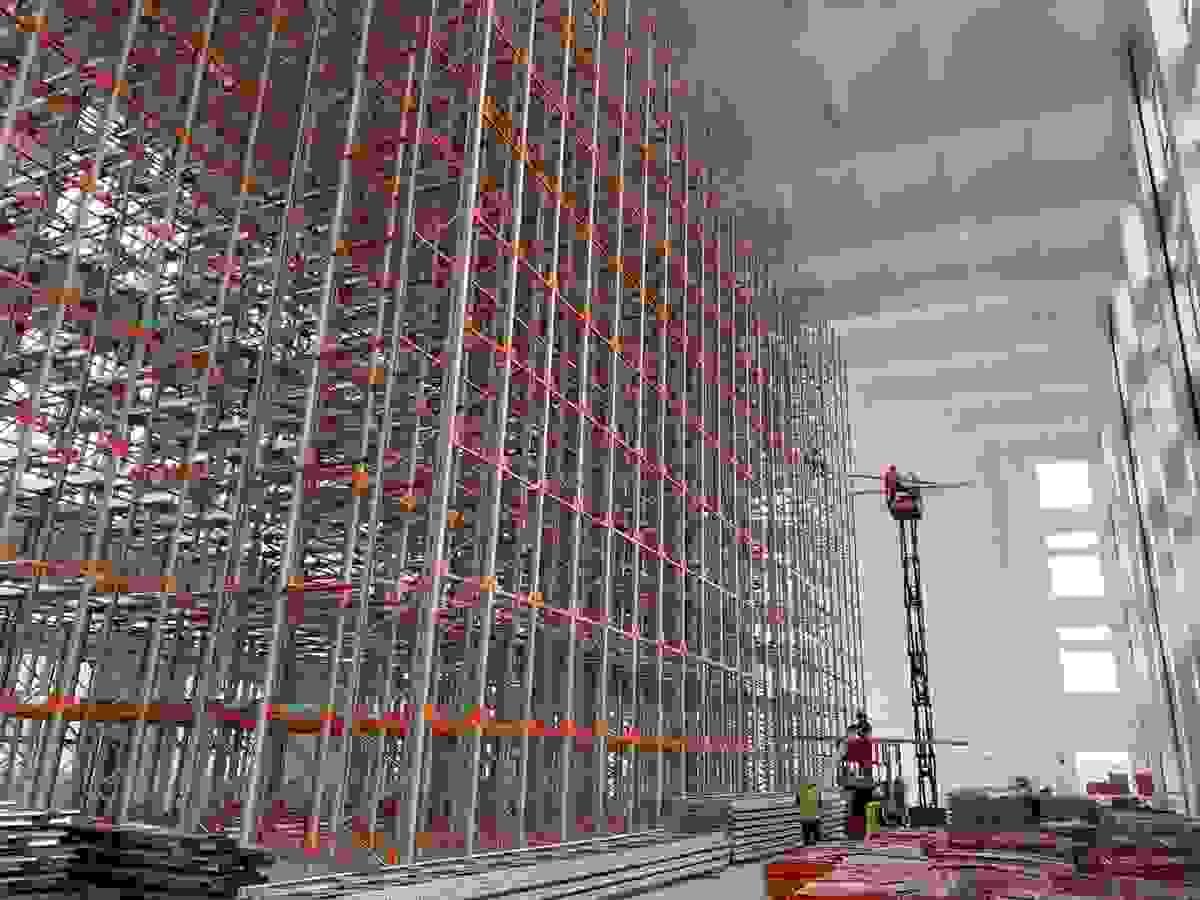

Welding Type AS/RS Racking

Country: China

time :2019

Product type :Welding Type AS/RS Rack

Warehouse type: Ambient temperature

Locations:4,500

Paint Point: Korean client prefers welding type of rack, such welding type requires high level fabrication skills, because welding can easily bend the post of rack, while ASRS requires high standard of error tolerance in vertical straightness.

Solution: We develop special tooling and specific procedure to ensure the straightness of posts.

This project also involved comprehensive testing to validate the structural integrity and performance of the racks under various loads, ensuring that they met both client specifications and industry standards. Our commitment to quality and precision has reinforced our reputation as a trusted partner in logistics solutions.

Robust Cantilever Racking

Country: Poland

Project time :2020

Product type :Cantilever Rack

Itemsstored :Long pipesWarehouse type: Normal Ambient

Racksheight :8.8m

Storage:5000 tonsThis solution provided efficient access and organization, significantly improving the client's operational workflow and safety standards. The robust design ensures durability under heavy loads, enhancing overall operational efficiency and reducing downtime.

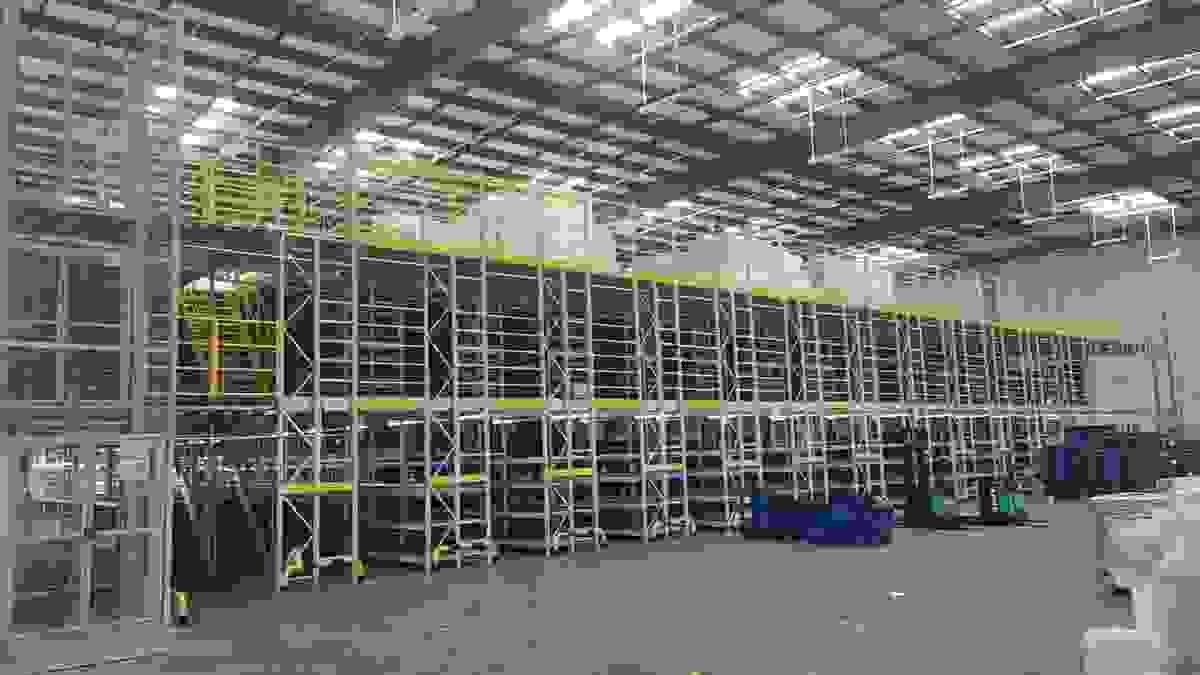

Shelving Rack Supported Mezzanine

Country: China

Project location :Xi‘an

Project industry :Footwear

Project time :2018

Product type :Rack supported mezzanine

Warehouse type: Normal Ambient

Racksheight :8m

Storagecapacity :9,704 ShelvesThis innovative solution significantly enhanced storage efficiency, allowing the client to optimize their inventory management and streamline warehouse operations. The design not only maximized vertical space but also provided a safe and accessible environment for workers, reinforcing operational productivity.

High Density Drive In Racking System

Country: Ecuador

Projecttime :2021

Product type :Drive in Rack

Racks height :10 mWarehouse type: Cold Room

Locations:2,200This solution maximized storage density while ensuring optimal temperature control for perishable goods.

The design also allows for easy access and efficient inventory management, enhancing the overall operational capabilities of the warehouse.

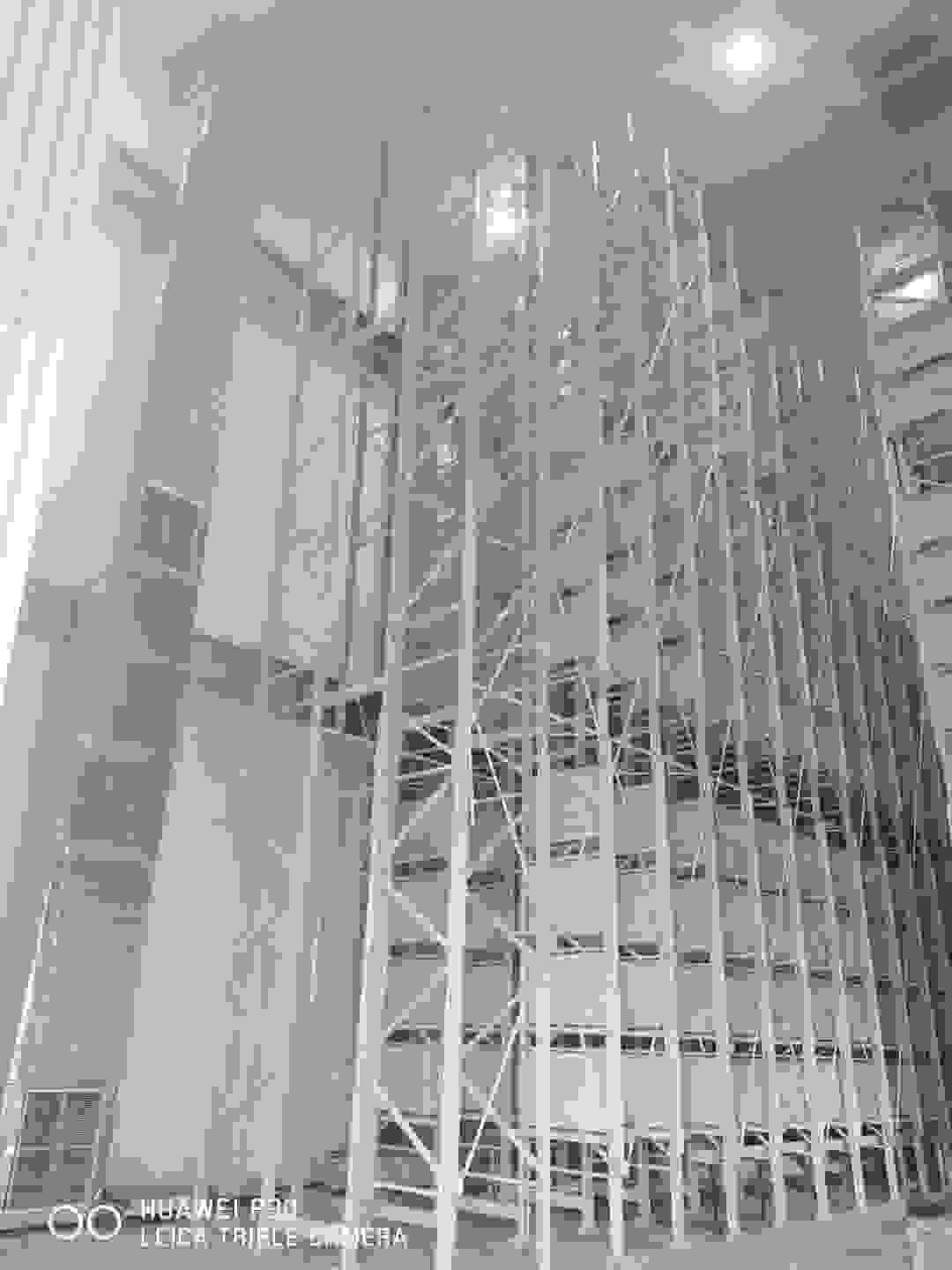

37m High Rack Supported Building for AS/RS System

Country: India

Projecttime :2023

Project location :Mumbai

Items stored :Textile products

Product type :Clad rack AS/RS

Warehouse type: Normal Ambient

Rack height :37 m

Locations:10,180Problem: The outdoor installation often encounters problem of racks getting rusty

Situation: We developed a method to increase the anti-rusty feature of racks

Results: The installation went smoothly approved by end user, and this advanced system optimizes space utilization and enhances inventory accessibility, ensuring efficient operations for our client in the textile industry. The installation has also facilitated improved workflow efficiency, enabling faster processing times and better inventory tracking, ultimately leading to enhanced customer satisfaction.

AS/RS System for mini-load

Country:China

Project time :2021

Project location :Yancheng city

Items stored :Batteries for cars

Product type : Mini-load AS/RS racking

Warehouse type: Normal Ambient

Rack height :19 m

Locations:8,180This implementation not only streamlined the storage process but also significantly improved the overall safety and efficiency of operations within the facility.

Furthermore, the system's scalability allows for future expansion, accommodating increased inventory demands while maintaining optimal performance and reducing operational costs.

High Density Shuttle Racking

Country:China

Project time :2015

Project location : Qingdao city

Items stored :food

Product type : Shuttle racking

Warehouse type: Normal Ambient

Rack height :9 m

Locations:6,700This solution effectively streamlined the client's operations, Allowing for faster inventory turnover and improved space utilization within the warehouse. The implementation also supported enhanced tracking systems, which contributed to better decision-making processes and optimized supply chain management.

Success Stories from Our Partners

ApexBeam's commitment to quality and innovation has been a game-changer for our warehousing needs. We are grateful for their expert guidance and the tailored solutions they provided, which have enhanced our operational efficiency significantly.

Efficient and Reliable

ApexBeam's racking solutions transformed our warehouse operations. Their team was professional and delivered on time, exceeding our expectations.

Exceptional Quality

The quality of the racks we purchased from ApexBeam is outstanding. Their products have significantly improved our storage capabilities.

Outstanding Support

The after-sales service provided by ApexBeam is unparalleled. They were responsive to our needs and helped us optimize our warehouse layout.Highlighted Heavy Duty Industrial Pallet Racking Installations

A glimpse into our successful and innovative projects that define our commitment to excellence.

© 2001-2025 All Rights Reserved by Nanjing Apexbeam Storage Equipment Co., LTD.