Heavy Duty Industrial Pallet Racking System

Maximize your warehouse efficiency with our expertly designed racks.

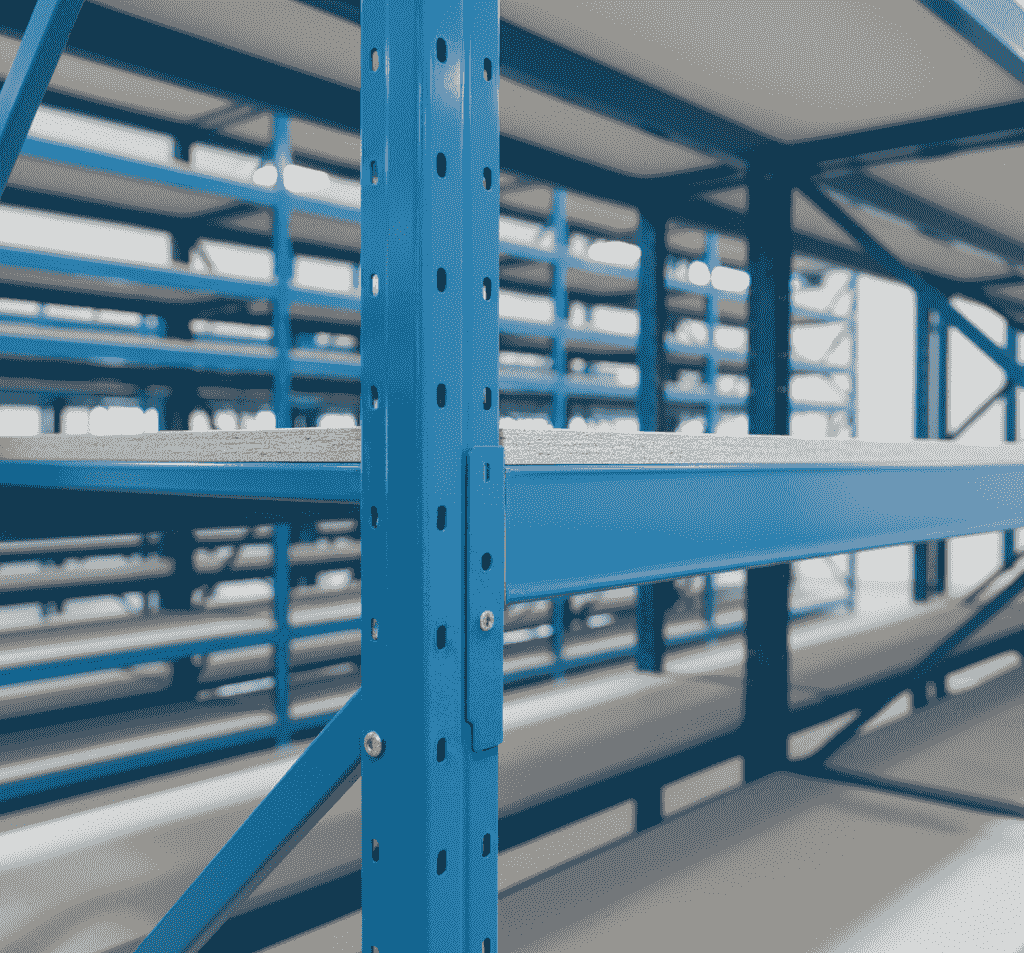

Heavy Duty Selective Pallet Rack for Direct Accessibility

Selective racks maximize storage density while ensuring direct access to every pallet, making them ideal for warehouses with high SKU variety and frequent item retrieval needs.

Direct Accessibility

Each pallet is individually accessible without moving others, eliminating the need for FIFO/LIFO restrictions. This speeds up loading/unloading and reduces handling time, especially beneficial for warehouses with diverse inventory turnover rates.

Space Efficiency

Vertical storage optimization minimizes aisle space while maintaining accessibility. Adjustable beam heights accommodate varying pallet sizes, allowing flexible use of cubic warehouse volume without sacrificing floor space.

Cost-Effective Scalability

Simple modular design enables easy expansion or reconfiguration. Lower initial investment compared to automated systems, with compatibility for forklifts or manual handling, adapting to business growth or seasonal demand changes.

Heavy Duty VNA (Very-Narrow-Aisle) Rack for Space Optimization

VNA racks maximize storage density by utilizing ultra-narrow aisles (typically 1.5–2m) with specialized forklifts

Space Optimization

VNA racks reduce aisle widths by 50–60% compared to traditional racks, dramatically increasing storage capacity within the same footprint. Ideal for high-cost real estate areas, this design allows warehouses to store more pallets without expanding their facility.

Specialized Equipment Compatibility

Designed for use with guided narrow-aisle forklifts or turret trucks, these racks ensure precise maneuvering in tight spaces. The equipment’s articulating or side-shifting capabilities enable safe and efficient pallet handling without aisle collisions.

Selective Accessibility

Despite narrow aisles, VNA racks provide direct access to every pallet (unlike drive-in racks). This balances high-density storage with inventory selectivity, making it suitable for warehouses with diverse SKUs requiring frequent stock rotation.

Shelving Rack-Cost-Effective Industrial Shelves

Shelving racks provide versatile, modular storage with open-access design - ideal for organizing small to medium-sized items in warehouses, retail, or offices - without requiring forklift access.

Adjustable Shelf Heights

Shelves can be repositioned to accommodate items of varying sizes, from boxes to bulk bins. This flexibility supports dynamic inventory needs and space optimization, making it adaptable for diverse industries like retail, archives, or parts storage.

Easy Accessibility

Open-front design allows direct, unobstructed access to stored items without handling interference. Workers can quickly locate and retrieve products, improving efficiency in order-picking or inventory management tasks.

Cost-Effective Simplicity

Requires minimal assembly and no specialized equipment (e.g., forklifts). Lightweight yet durable materials (steel/wire) reduce upfront costs and maintenance, making it a practical choice for SMEs or low-budget storage solutions.

Gravitational Flow Racks for Easy Picking

Gravity flow racks utilize inclined rollers to enable automatic product movement via gravity, ensuring FIFO inventory rotation for high-density storage with minimal manual operation

FIFO Inventory Control

Gravity flow racks naturally enforce first-in-first-out (FIFO) stock rotation as products glide forward on inclined rollers. Ideal for perishable goods or time-sensitive materials, this eliminates manual sorting errors and ensures consistent product freshness or batch tracking.

High-Density, Low-Energy Design

By leveraging gravity for product movement, these racks reduce reliance on powered conveyors, cutting energy costs. Their compact lane-based layout maximizes storage density while maintaining accessibility, perfect for warehouses with space constraints.

Ergonomic & Safe Handling

Products automatically advance to the picking face, minimizing worker bending or reaching. Roller systems operate quietly and smoothly, reducing physical strain and accident risks compared to manual pallet retrieval methods.

High-Density Drive-In Rack for Highly Productive Warehouse Solution

Drive-in racks maximize storage density by allowing forklifts to drive directly into the rack structure, enabling high-volume pallet storage with last-in-first-out (LIFO) inventory management for bulk or single-SKU warehouses.

High-Density Storage

Drive-in racks eliminate aisles by storing pallets in continuous lanes, utilizing up to 75% more space than selective racks. Ideal for homogeneous SKUs with low turnover, this design reduces warehouse footprint while maintaining large-volume storage capacity.

LIFO Inventory System

Pallets are loaded and unloaded from the same aisle, enforcing a last-in-first-out flow. This suits non-perishable bulk goods (e.g., beverages, raw materials) where stock rotation isn’t critical, streamlining operations for low-variety, high-volume warehouses.

Structural Durability

Constructed with heavy-duty beams and uprights to withstand repeated forklift entry. Reinforced guide rails ensure precise pallet placement and minimize product damage, even under high-frequency loading/unloading cycles.

Heavy Duty Push-Back Racks for High-Density Storage

Push-back racks maximize storage density by utilizing a "last-in, first-out" (LIFO) system where loaded pallets push forward on rolling or skid tracks, consolidating inventory in deep lanes while minimizing aisle space.

High-Density Storage

Push racks store multiple pallets deep (typically 2–6 pallets per lane) by sliding them on inclined rollers or skids. This reduces aisle requirements by up to 80% compared to selective racks, ideal for bulk storage of homogeneous goods with low SKU variety.

LIFO Inventory Management

Designed for LIFO operation, newly loaded pallets push existing ones forward. Suited for non-perishable or non-time-sensitive products (e.g., paper, canned goods), though less flexible than FIFO systems.

Reduced Forklift Traffic

The design of push back racks minimizes the need for excessive forklift traffic, enhancing safety and reducing the risk of accidents within your warehouse. This feature also leads to more efficient picking operations and a smoother workflow.

HeavyDuty Cantilever Racks for Lumber & Pipe Storage

Cantilever racks feature open-front, arm-supported designs ideal for storing long, bulky, or irregularly shaped items (e.g., pipes, lumber, furniture) without vertical obstructions, enabling easy side-loading and unloading.

Unobstructed Storage Space

With no front columns, cantilever racks allow full-length item storage and direct side access. This eliminates width restrictions, making them perfect for oversized materials like steel bars, carpets, or PVC tubes that cannot fit in standard pallet racks.

Adjustable Arms

Arms can be repositioned or removed to customize spacing for varying load sizes. This adaptability supports diverse inventory types—from small bundles to large panels—while maintaining structural stability under heavy weights.

Durability for Heavy Loads

Built with heavy-duty steel frames and reinforced bases, cantilever racks withstand extreme weights (up to several tons per arm). Ideal for industrial or construction settings where robust, long-term storage is critical.

Multi-tier Mezzanine/Rack Supported Mezzanie for Vertical Space Utilization

Multi-tier mezzanines provide an efficient solution for maximizing storage space within your warehouse. These systems allow for the creation of additional levels, enabling the stacking of products vertically and making the most out of your existing footprint.

Our designs ensure that businesses can adapt their storage configurations as needs change, offering a seamless way to enhance productivity and organization.

Vertical Space Optimization

By adding elevated tiers (typically 2–3 levels), these racks double or triple storage capacity without expanding the building footprint. Ideal for low-ceiling facilities, they transform unused overhead space into functional storage or workspace for inventory, equipment, or even offices.

Customizable Layouts

Modular designs allow flexible configurations—open shelving, pallet racks, or workstations—to adapt to changing needs. Guardrails, stairs, and conveyors can be integrated for safety and workflow efficiency, supporting diverse operations like order picking or bulk storage.

Cost-Effective Expansion

Cheaper than facility relocation or construction, mezzanine racks offer a scalable solution for growing storage demands. Quick assembly and disassembly enable reconfiguration or relocation, reducing long-term capital investment compared to permanent structures.

High Density Shuttle Racking - Semi-Automation, FIFO/LIFO Flexibility

Shuttle racks automate high-density storage with battery-powered robotic shuttles that transport pallets within deep lanes, enabling semi-automated FIFO or LIFO operations while minimizing aisle space.

Semi-Automated Pallet Handling

Battery powered robotic shuttles replace forklifts for pallet movement within lanes, reducing labor and human error. Operators only need to load/unload at the lane entrance, while shuttles autonomously store/retrieve pallets, boosting efficiency in cold storage or high-throughput warehouses.

High-Density FIFO/LIFO Flexibility

Configured for either First-In-First-Out (FIFO) or Last-In-First-Out (LIFO) workflows, shuttle racks adapt to perishable goods or bulk inventory. Deep-lane designs (10+ pallets per lane) maximize space utilization by up to 60% compared to traditional racks.

Scalable Modular Design

Systems can expand by adding lanes or shuttles without structural changes. Compatible with various pallet sizes/weights, they integrate seamlessly with WMS for real-time inventory tracking, ideal for growing operations needing gradual automation upgrades.

AS/RS Racking - Fully Automated High Density Storage

ASRS (Automated Storage and Retrieval System) racks integrate robotic cranes and software-controlled platforms to enable fully automated, high-density storage and retrieval of goods with minimal human intervention, optimizing space and efficiency in warehouses.

Full Automation & Precision

Computer-controlled cranes or shuttles navigate vertical/horizontal axes to store/retrieve items with millimeter accuracy. Linked to WMS/ERP systems, they eliminate manual errors while operating 24/7, ideal for pharmaceuticals or electronics requiring traceability and speed.

Ultra-High-Density Storage

By utilizing vertical clearance (up to 45m) and narrow aisles, ASRS racks achieve 85%+ space utilization—far surpassing traditional racks. Ideal for urban warehouses with limited footprints but high SKU volumes.

Scalable Modularity

Systems expand vertically or horizontally via modular components. Compatible with bins, pallets, or trays, they adapt to diverse loads (1kg–2+ tons) and future tech upgrades like AI-powered inventory forecasting.

A rack-supported building (self-supporting clad rack SILO, "building rack") integrates structural storage racks as the primary load-bearing framework, combining warehousing functionality with building support to maximize space efficiency and reduce construction costs.

Dual-Purpose Structural Design

The storage racks serve as both shelving and the building’s main support, eliminating the need for separate columns or walls. This hybrid approach reduces material costs and construction time while optimizing storage density in distribution centers or manufacturing plants.

© 2001-2025 All Rights Reserved by Nanjing Apexbeam Storage Equipment Co., LTD.